Let is clear up a common misconception right away: not all knockout machines are created equal. While sand foundries typically rely on vibratory shakeout tables, pneumatic knockout machines serve a specialized—and surprisingly satisfying—role in investment casting operations. Think of them as the precision dentists of the casting world: targeted, effective, and far gentler than brute force.

At Laxminarayan Technologies, we have spent decade perfecting this exact art, and our pneumatic knockout systems at https://www.ic-machines.com/are engineered specifically for the unique demands of modern foundries.

What Exactly Is Knockout in Foundry Operations?

In foundry terminology, "knockout" describes the critical process of separating solidified metal castings from their surrounding mold material. This step bridges product and finish—get it incorrect, and you risk damaged parts or waste labor. The method varies dramatically based on your casting process.

Sand casting operations predominantly use vibratory shakeout machines that agitate entire mold flasks to release castings. Investment casting, however, demands a different approach. Moreover, After the dewaxing and pouring stage, your metal parts remain encased in a hard ceramic shell. That is where pneumatic knockout shine—and where Laxminarayan Technologies delivers unmatched precision.

The Pneumatic Advantage in Investment Casting

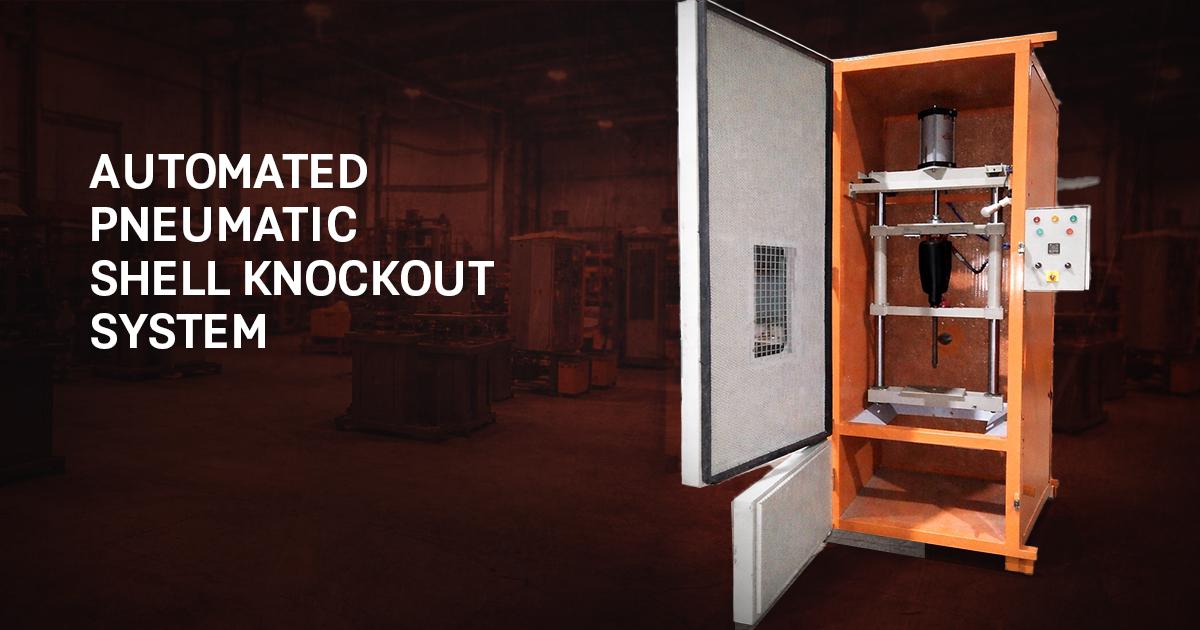

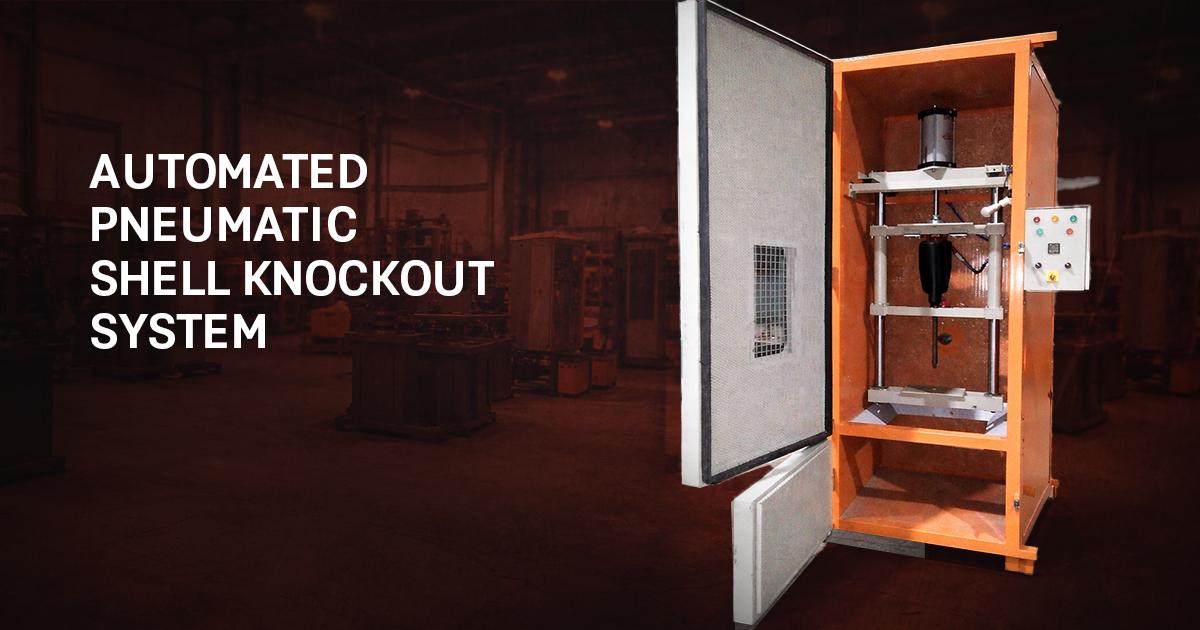

Pneumatic knockout machines deploy controlled, high-impulse hammering to fracture ceramic shells without harming the delicate metal castings inside. Image a specialised air hammer mounted on an adjustable carriage, paired with an amphitheater-style anvil that securely clamps casting trees during operation.

Nevertheless, Here is the practical workflow our system at https://www.ic-machines.com/are designed to execute flawlessly:

1.unCooling First: Castings must fully solidify and cool before knockout—rushing this step risks thermal shock damage.

2.Secure Positioning: Operators place the ceramic-encased casting tree into pneumatic jaws that hold it firmly without distortion.

3. Controlled Impact: The pneumatic hammer delivers rapid, adjustable blows to strategic points on the shell. Unlike manual chiseling (which risks nicking your cast), this method offer repeatable precision.

Furthermore, 4. Shell Fragmentation: Ceramic cracks along natural stress lines, falling away cleanly while your metal parts remain intact.

Therefore, The UK is Health and Safety Executive actually recommends non-contact knockout methods where possible—pneumatic systems with proper guarding fit this requirement beautifully by keeping operators at a safe distance during shell fragmentation.

Why Vibratory Methods Fall Short for Ceramic Shells

You may be thinking, "Is there a reason that with vibration methods used for sand molds, they wouldn't be beneficial to ceramic shells?" The answer is two-fold.

Material Characteristics — In comparison to sand molds, which easily break apart due to lack of vibration, ceramic shells are hard enough and can be easily destroyed from hitting something but have great resistance to being separated by vibratory action.

Part Complexity — Because of their thin walls and complex geometries, investment castings will suffer enough fatigue or distortion as a result of being subjected to excessive vibration that separation from a shell could occur prior to actual shell separation. This is why we at Laxminarayan Technologies use an exclusive aeration pneumatic solution for investment casting; we recognize that there is no such thing as a universal methodology for effecting precision foundry operations.

Choosing the Right Pneumatic Knockout Equipment

When evaluating pneumatic knockout systems, prioritize these critical features—standards we uphold at https://www.ic-machines.com/

-Adjustable Impact Force: Different shell thicknesses and alloy type require tailored hammer energy. Therefore, Our machines offer precise control to match your specific casting requirements.

-Ergonomic Clamping: Look for quick-change fixtures that accommodate various casting tree configurations. Laxminarayan Technologies design clamping systems that minimize operator fatigue while maximize security.

-Dust Extraction Integration: Ceramic fragmentation generates fine particulates—OSHA and foundry safety standards demand proper ventilation. Our systems integrate seamlessly with existing dust collection infrastructure.

- Operator Controls: Foot pedals or two-hand controls prevent accidental activation during loading. Safety is not an add-on at Laxminarayan Technologies—it is engineered into every component.

Reputable manufacturer like Laxminarayan Technologies offer system with variable-position carriage to reach complex geometries without manual repositioning. Our engineering team at https://www.ic-machines.com/ works directly with foundries to customize solutions that address unique operational challenges.

Safety & Efficiency: The Real ROI

A well-executed knockout process is not just about speed—it directly impacts your bottom line. Therefore, Effective shell removal reduce secondary grinding time, minimizes cast damage (and scrap rates), and accelerates throughput.

One foundry manager we worked with at Laxminarayan Technologies joked, "Your pneumatic knockout machine paid for itself in three months—not because it is fast, but because our finishing crew stopped complaining about chipped edges." That is the kind of feedback that validates our engineering philosophy: precision over power, reliability over flash.

The Bottom Line: Specialization Matters

Pneumatic knockout machines solve a specific problem brilliantly: removing ceramic shells from investment castings with precision and repeatability. They're not universal foundry tools—they're specialists. Understanding this distinction prevents costly equipment mismatches and process inefficiencies.

At Laxminarayan Technologies, we believe knockout isn't an afterthought. It's the crucial handoff between your casting process and final finishing. Invest in the right method for your operation—whether vibratory for sand molds or pneumatic for ceramic shells—and your quality metrics (and maintenance team) will thank you.

Ready to explore how Laxminarayan Technologies can optimize your knockout process? Visit https://www.ic-machines.com/to discover our complete range of pneumatic knockout solutions engineered specifically for investment casting excellence.