The aerospace sector continues to evolve rapidly, driven by the need for lighter, more aerodynamic, and efficient aircraft designs. Among the crucial components driving this innovation is the aircraft wing — a structure that defines stability, control, and efficiency in flight. Modern aerospace engineering has transformed wings into intelligent structures capable of responding dynamically to flight conditions.

The US Aero Wing Market is a key player in this evolution, focusing on the development of high-strength, low-weight, and fuel-efficient wing designs. The market is being shaped by increased adoption of advanced materials, computational design tools, and aerodynamic simulation systems that allow engineers to enhance lift and performance while minimizing drag.

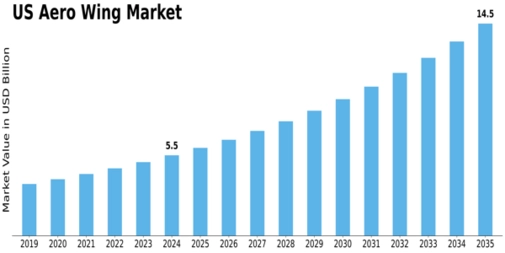

Market Growth and Industry Analysis

According to recent market analysis, this industry has shown steady growth due to innovations in design technology and manufacturing precision. Engineers are focusing on materials that deliver strength without compromising flexibility, optimizing aircraft efficiency and reducing environmental impact.

Emerging Trends

Key trends influencing the market include modular wing architectures, active flow control systems, and digital twin modeling. Such advancements allow engineers to predict wing performance under various stress conditions, leading to safer and more efficient aircraft.

Future Outlook

The forecast for the U.S. aero wing industry indicates ongoing advancements in additive manufacturing and aerodynamic shaping, ensuring improved energy efficiency and flight control.

FAQs

1. What is driving innovation in aero wing design?

Lightweight materials, digital simulations, and energy-efficient architectures are major drivers.

2. How do advanced wings impact aircraft performance?

They improve lift-to-drag ratios, reduce fuel use, and enhance maneuverability.