The aerospace industry in the United States is witnessing a major transformation, thanks to the advent of 3D printing technology. Known as additive manufacturing, 3D printing is reshaping how aircraft components are designed, produced, and maintained. This technology’s precision and flexibility are helping manufacturers reduce waste, enhance structural integrity, and accelerate the pace of innovation across aviation sectors.

The US Aerospace 3D Printing Market has emerged as a vital segment of the national aerospace ecosystem. From lightweight engine parts to intricate cabin structures, 3D printing allows engineers to achieve complex geometries that were previously impossible using traditional techniques. Moreover, the ability to customize and produce components on demand has drastically reduced lead times and improved production efficiency.

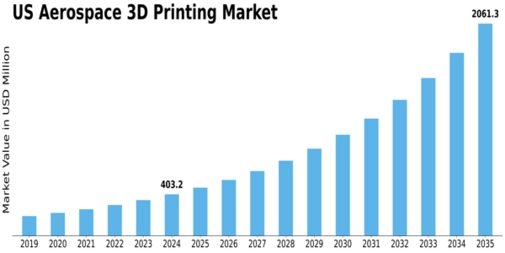

Market Growth and Advancements

The market’s continuous evolution is supported by innovations in materials science and digital manufacturing systems. As sustainability and performance optimization become critical priorities, 3D printing offers an environmentally friendly and cost-effective approach to aircraft production.

According to recent market analysis, the industry’s growth is being driven by several factors including advanced material development, government support for research initiatives, and an increasing demand for faster prototyping solutions. Engineers can now design lightweight yet durable components that withstand the extreme conditions of aerospace operations while reducing overall aircraft weight and fuel consumption.

Market Trends and Innovations

Emerging trends show how the aerospace sector is integrating 3D printing into every stage of aircraft design and maintenance. Additive manufacturing enables rapid prototyping, efficient spare parts production, and component consolidation, resulting in lighter, more efficient aircraft. The capability to print high-performance polymers and metal alloys has further strengthened the role of 3D printing in both defense and commercial aviation.

The U.S. is at the forefront of this transformation, with continuous research and technological investment shaping the next generation of aerospace design. Engineers are leveraging advanced software and automation tools to produce highly precise and customizable components.

Market Size and Share Dynamics

The market size of the US Aerospace 3D Printing segment continues to expand due to the rising integration of this technology across various applications. Its share in the aerospace supply chain is growing as manufacturers seek flexible, scalable, and digital-first production models. The technology supports everything from tooling to end-use parts, allowing aerospace companies to enhance performance and reduce dependence on traditional supply chains.

The application of additive manufacturing extends beyond aircraft manufacturing. It plays a significant role in space exploration, satellite component production, and unmanned aerial systems — all of which benefit from reduced weight and improved performance through advanced 3D-printed structures.

Key Benefits Driving Adoption

The adoption of aerospace 3D printing offers numerous operational and economic benefits:

- Design Freedom: Engineers can innovate without limitations, producing parts with complex geometries.

- Weight Reduction: Lightweight structures improve aircraft fuel efficiency and payload capacity.

- Sustainability: Reduced material waste supports eco-conscious manufacturing goals.

- Faster Prototyping: Rapid iteration shortens design-to-production timelines.

These advantages make 3D printing a strategic enabler of modernization across U.S. aerospace programs.

Future Outlook

The forecast for the US Aerospace 3D Printing Market suggests continued expansion as research into materials and process optimization progresses. Emerging technologies like AI-driven design, digital twins, and automation are further enhancing the accuracy and repeatability of 3D printing. As aerospace manufacturers continue to adopt digital transformation strategies, additive manufacturing is expected to become a core production method for both structural and non-structural aircraft components.

Sustainability and cost efficiency will remain key market drivers. As environmental regulations tighten, the ability to create lighter aircraft using recycled or advanced materials will define the industry’s competitive edge. The ongoing evolution of printing techniques, including metal powder bed fusion and direct energy deposition, will unlock new possibilities for producing high-strength aerospace-grade parts.

Conclusion

The US Aerospace 3D Printing Market stands at the intersection of technology, innovation, and sustainability. As aerospace manufacturers embrace digital production systems, the industry is moving closer to a future where aircraft components are not only lighter and stronger but also produced with minimal waste and maximum precision. This transformation marks a significant step toward the next era of aviation — one powered by innovation and efficiency.

FAQs

1. How is 3D printing revolutionizing aerospace manufacturing in the U.S.?

3D printing allows faster, more precise, and cost-efficient production of complex aircraft components, reducing waste and enhancing performance.

2. What are the main factors driving the growth of the US Aerospace 3D Printing Market?

Innovation in materials, rising sustainability goals, and the demand for rapid prototyping are the key growth factors.