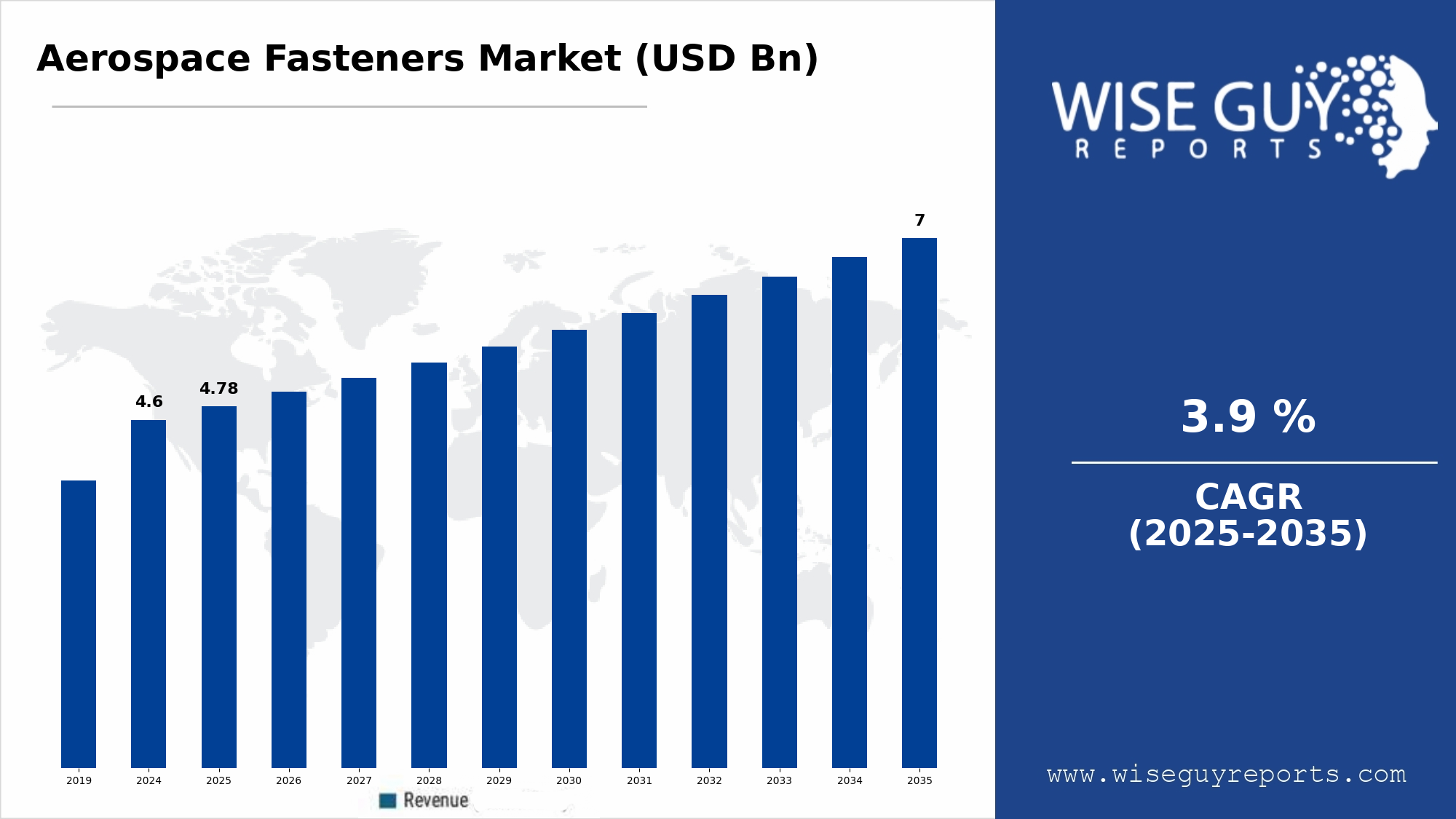

The Aerospace Fasteners Market occupies a crucial niche within the broader aerospace components industry by supplying essential mechanical fixings that maintain aircraft integrity and performance. As per WiseGuyReports, the Aerospace Fasteners Market is projected to have grown from 4,780 USD million in 2025 to 7 USD billion. The aerospace fasteners market is anticipated to develop at a compound annual growth rate (CAGR) of approximately 3.9% from 2025 to 2035.2035.

Aerospace fasteners may be small in size, but they are among the most critical components in aircraft construction, assembly, and maintenance. Fasteners like rivets, screws, bolts, and nuts help join structural elements, engine mounts, and interior fixtures while providing resilience against high vibration and temperature fluctuations experienced in flight. Their reliability directly impacts safety, performance, and aircraft service life.

The Aerospace Fasteners Market benefits from several growth drivers, including increasing aircraft production by major OEMs and rising demand for new commercial and military aircraft. With global air travel resuming to pre-pandemic levels and manufacturers such as Boeing and Airbus expanding production, fasteners remain in consistently high demand to support assembly lines and MRO operations. Recent industry developments also show strong demand for specialized fasteners; for instance, Boeing faced challenges securing specific nuts and bolts for its 737 MAX production, highlighting the strategic importance of reliable fastener supply chains.

A key market trend is the adoption of advanced manufacturing technologies such as 3D printing and automation, which enhance production precision and efficiency. These technologies allow fastener manufacturers to produce complex designs tailored to specific aerospace applications, reduce material waste, and shorten lead times. Automated assembly systems also improve consistency, which is crucial for high-volume aircraft production.

From an industry analysis standpoint, material innovation is shaping the future of aerospace fasteners. The shift toward lightweight materials like titanium and composites supports broader industry goals of fuel efficiency and emissions reduction. Fasteners made from titanium deliver high strength with reduced weight, making them ideal for critical structural applications, particularly in modern aircraft designs that prioritise performance and sustainability.

Another significant trend is growing collaboration and consolidation among industry players. Notable industry moves include acquisitions aimed at expanding product portfolios and enhancing global reach. For example, Howmet Aerospace’s acquisition of Stanley Black & Decker’s aerospace unit — a business specialising in fasteners and engineered components — strengthens its position in fastener production and supply for major aerospace OEMs.

Regional dynamics also influence the aerospace fasteners market. North America dominates market share due to its advanced manufacturing base, strong defence sector, and substantial investments in aviation R&D. Europe and Asia-Pacific are key growth regions as well, the former due to technological innovation and defence contracts, and the latter due to rising air travel and aircraft production capacities in countries such as China and India.

Looking ahead, the Aerospace Fasteners Market Forecast points to continued opportunities arising from rising MRO (Maintenance, Repair & Overhaul) demand and expanding applications in adjacent sectors such as urban air mobility and space exploration. As aerospace systems become more complex, fasteners that offer enhanced performance, reliability, and weight savings will continue to find strong demand, ensuring stable market growth.