Finding the right partner for your technical needs is a challenge in today's fast-paced market. Industrial and manufacturing operations achieve their complete success through two essential elements, which are precision and reliability. Top-tier INSPECTION EQUIPMENT SUPPLIERS do more than just ship crates of high-tech hardware to your door. The company functions as a consulting partner who possesses knowledge about the specific operational challenges that your business encounters. Selecting a vendor requires a deep dive into their after-sales support and calibration capabilities. This guide will help you navigate the complex landscape of modern hardware procurement with total confidence.

Ensuring Future Success

The choices you make today regarding your hardware will echo through your operations for many years. It is about finding a balance between cutting-edge innovation and the solid reliability of proven engineering. A true partner will stick by you when a machine fails or when a new regulation changes the game. They provide the steady hand and the sharp tools needed to keep our world running safely. By focusing on quality over the lowest bid, you protect your reputation and your bottom line. Take the time to vet every candidate thoroughly before signing a long-term contract.

Prioritizing Technical Support and Team Expertise

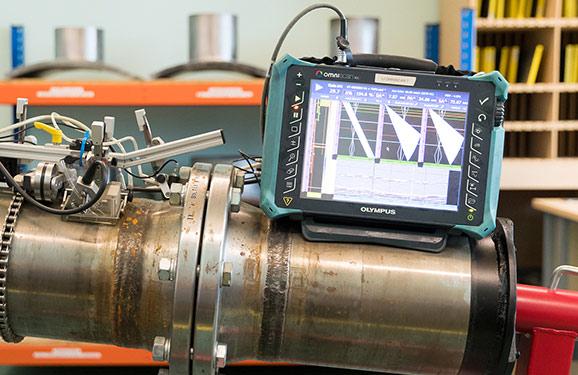

A shiny new piece of hardware is useless if your team cannot operate it. Great vendors offer more than just a manual and a basic warranty for their products. Many leading organizations now require their staff to complete Eddy Current Training Courses, like the one from RVS Quality Certifications Pvt. Ltd., to master advanced surface inspections. A supplier who allows this kind of professional growth is invaluable. They facilitate the transition from complex electromagnetic theory to practical, on-site application for your technicians. This level of educational support assures that your investment yields accurate and repeatable results.

Customizing Tools for Specialized Industry Needs

Not every project requires a standard, off-the-shelf solution from a giant global warehouse. Sometimes, the unique physical demands of your niche necessitate specialized gear. Companies like DRH Sports understand that high-performance environments require specialized equipment that can withstand rigorous, daily physical use. While they lead in their field, the principle of choosing "fit-for-purpose" gear applies to all technical sectors. Whether you are testing athletic gear or industrial valves, the hardware must be ergonomic and tough. Customization ensures that your team stays productive without fighting against poorly designed or flimsy tools.

Evaluating Long-Term Structural Reliability Standards

The safety of large-scale infrastructure depends heavily on the tools used during the initial build. Substandard testing gear can lead to missed defects and catastrophic failures in the coming years. Maintaining BUILDING STRUCTURAL STABILITY requires highly sensitive sensors that can detect internal fatigue before it becomes visible. You should ask potential vendors for case studies involving high-stress environments like bridges or skyscrapers. A supplier with a proven track record in heavy civil engineering is usually a safe bet. Their equipment must meet the rigorous standards demanded by modern architectural safety codes and regulations.

-

Certification of sensor accuracy against international metrology standards.

-

Durability of handheld units in extreme weather or high-dust conditions.

-

Battery life and field-serviceability of remote monitoring hardware.

-

Software compatibility with existing project management and CAD platforms.

Assessing Digital Integration and Data Security

Modern testing no longer relies solely on physical dial readings. We live in an era where data must be beamed instantly to the cloud. You must ensure that your hardware partner prioritizes cybersecurity and seamless data integration in their software. We must protect field-gathered information from tampering and make it accessible to authorized engineers worldwide. Ask about the encryption levels used in their wireless transmission protocols during your initial meetings. A supplier who ignores digital security is a liability in our interconnected industrial world of 2026.

-

Real-time cloud syncing for immediate remote data analysis.

-

End-to-end encryption for all transmitted inspection reports and files.

-

User-friendly interfaces that reduce the risk of human entry errors.

-

Automatic firmware updates to protect against the latest digital threats.

Integrating External Verification Protocols

Quality control needs implementation across multiple departments and throughout an entire organization instead of remaining confined to one location. Reliable vendors often collaborate with outside experts to validate the performance of their latest machines. Utilizing Third-Party Inspection Services helps confirm that the equipment performs exactly as the manufacturer claims it will. The quality of a vendor's operations becomes transparent when they permit external parties to conduct audits. It builds a foundation of trust that is essential for long-term business partnerships and growth.

Moving Toward Excellence

Ultimately, the goal is to create a seamless workflow where the technology supports the human expert. When the right tools meet the right hands, the results are always superior and more dependable. This synergy is what separates market leaders from those who simply struggle to keep up with trends. Dedication to precision is not just a business strategy; it is a commitment to the safety of the general public. Your commitment to excellence will be the legacy you leave behind in every project you complete.