In modern manufacturing, achieving precision, efficiency, and repeatability in metal joining is critical. Central to this process is the welding gun, a versatile and essential tool used across industries from automotive and aerospace to electronics and heavy machinery. For manufacturing engineers, OEMs, and automation integrators, understanding welding guns’ types, principles, and best practices is crucial for optimizing production lines.

Heron Welder, a global leader in industrial welding solutions, offers a complete range of high-performance welding guns and automated systems designed to enhance productivity and ensure consistent quality.

What is a Welding Gun?

A welding gun is a device that delivers electrical energy to metal workpieces, facilitating controlled fusion or joining. In resistance welding processes, the welding gun typically includes electrodes that clamp the metal parts while a precise current passes through them. The generated heat, caused by electrical resistance at the interface of the metals, melts the material locally, creating a strong weld upon cooling.

Welding guns are designed for various methods, including:

-

Spot Welding – Joining overlapping metal sheets at discrete points.

-

Projection Welding – Using raised sections (projections) to concentrate heat and create uniform welds.

-

Seam Welding – Producing continuous welds along joints, often for leak-proof applications.

-

Capacitor Discharge Welding (CDW) – Ideal for thin sheets or small components, delivering high-intensity pulses.

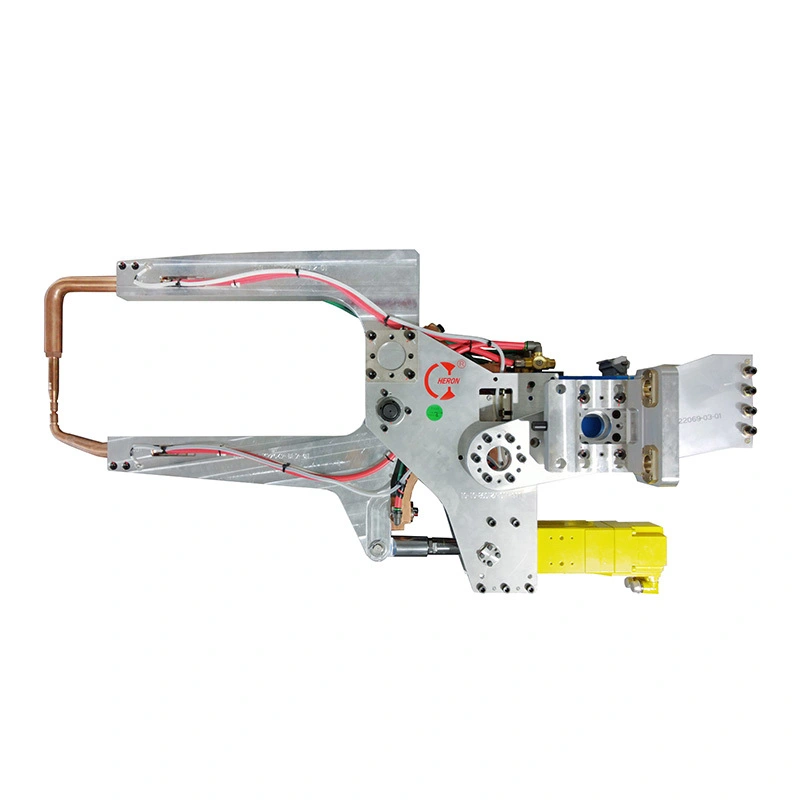

Key Components of a Welding Gun

Understanding a welding gun’s components is essential for optimizing its use:

-

Electrodes: Conduct electrical current and apply pressure; their material and geometry directly influence weld quality.

-

Gun Arm or Frame: Provides stability and precise alignment for repeatable welds.

-

Cooling System: Maintains optimal temperature to prevent electrode wear and overheating.

-

Trigger and Control Interface: Allows operators to manage timing, current, and pressure.

-

Cables and Connectors: Deliver consistent electrical power to the electrodes.

Heron’s welding guns integrate these components with advanced ergonomic and automation features, making them suitable for manual, semi-automatic, or fully robotic production lines.

Applications of Welding Guns in Industry

Welding guns are widely applied in diverse industrial sectors:

Automotive Manufacturing

Spot and projection welding guns are indispensable in car body assembly. They ensure strong, reliable joints in high-volume production while minimizing distortion.

Electrical and Electronics Components

Capacitor discharge welding guns allow precise joining of small, delicate components like battery packs, connectors, and terminals.

Heavy Equipment and Machinery

Seam and projection welding guns join thicker metal plates used in construction equipment, agricultural machinery, and industrial frameworks.

Aerospace and Transportation

High-precision guns are used in lightweight aluminum and alloy structures, ensuring high-strength joints without compromising material integrity.

Types of Welding Guns

Selecting the right welding gun depends on the materials, thickness, and production requirements. Key types include:

-

Manual Welding Guns – Operator-controlled, suitable for small batches or maintenance tasks.

-

Robotic Welding Guns – Integrated with automated production lines, offering high precision and repeatability.

-

Pneumatic or Hydraulic Guns – Use controlled pressure to achieve uniform welds in high-speed applications.

-

Capacitor Discharge Guns – Deliver fast, high-energy pulses for small components or delicate materials.

Heron Welder provides a comprehensive lineup that covers all these types, tailored to OEMs, automation integrators, and industrial manufacturers.

Best Practices for Using Welding Guns

Optimizing welding gun performance requires attention to both equipment and process:

-

Electrode Maintenance: Regular inspection and dressing prevent weld defects and extend gun life.

-

Current and Pressure Calibration: Ensures consistent weld penetration and prevents overheating.

-

Workpiece Preparation: Clean surfaces improve conductivity and reduce spatter.

-

Cooling and Duty Cycle Management: Proper cooling prevents electrode degradation and downtime.

-

Automation Integration: Pairing welding guns with Heron’s robotic controllers enhances repeatability and throughput.

Implementing these practices can significantly reduce production errors, lower maintenance costs, and increase overall efficiency.

Heron Welder: Your Partner in Welding Gun Solutions

As a global manufacturer, Heron Welder specializes in delivering complete welding solutions, including advanced welding guns, controllers, and fully automated production lines. Whether you need spot, projection, seam, or capacitor discharge welding, Heron’s equipment ensures:

-

Precise, repeatable welds

-

High-speed production capabilities

-

Ergonomic and maintenance-friendly designs

-

Customizable solutions for unique applications

Heron also offers technical support and consultation to help manufacturers select the right welding gun setup, integrate automation, and maximize ROI.

Welding Gun FAQs

1. How do I choose the right welding gun for my application?

Consider metal type, thickness, production speed, and automation needs. Heron’s experts can recommend customized solutions.

2. What maintenance is required for welding guns?

Regular electrode dressing, cooling system checks, and current calibration are critical to maintain performance and prevent defects.

3. Can welding guns be used in fully automated robotic lines?

Yes, Heron offers robotic welding guns designed for high-precision, high-volume production environments.

4. What is the difference between spot welding and projection welding guns?

Spot welding uses flat electrodes for discrete welds, while projection welding concentrates heat on raised sections for uniform multi-point joins.

5. Are Heron welding guns suitable for delicate components like battery packs?

Absolutely. Capacitor discharge and precision spot welding guns are designed for small, sensitive, or thin metal parts.

Conclusion: Optimize Your Production with Heron Welding Guns

Choosing the right welding gun is critical to achieving efficiency, quality, and repeatability in industrial metal joining. From automotive assembly lines to battery manufacturing, Heron Welder provides expertly engineered solutions, combining robust equipment, automation compatibility, and technical support.

Ready to upgrade your production line? Contact Heron today to request a quote or consult with our experts for customized welding and automation solutions tailored to your manufacturing needs.