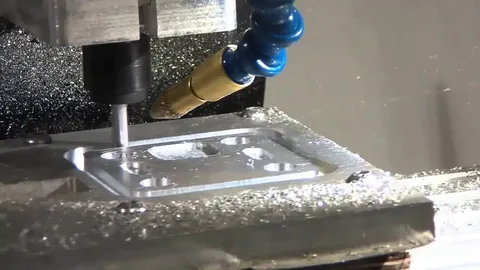

Custom CNC milling has become a game-changer for modern manufacturing, offering unmatched precision, efficiency, and flexibility across a wide range of sectors. From aerospace to medical devices, the ability to create highly accurate components with minimal errors is reshaping how industries operate. As demand grows for tighter tolerances and rapid turnaround times, businesses increasingly rely on custom CNC milling to produce complex parts tailored to their exact requirements. This technology not only streamlines production processes but also enhances product quality and consistency.

By utilizing advanced computer-controlled machines, industries can manufacture prototypes, small batches, and large-scale production orders with greater speed and accuracy. Custom CNC milling allows designers and engineers to experiment with more intricate shapes and complex geometries without sacrificing precision. As a result, innovative ideas are brought to life faster, helping companies remain competitive. Below are the top industries where custom CNC milling plays a vital role in supporting innovation, reducing production costs, and improving end-product performance.

Aerospace and Defense Industry

The aerospace and defense industry demands components that meet extremely high safety standards and tight tolerances. Custom CNC milling is essential in producing high-precision aircraft parts such as engine housings, landing gear components, turbine blades, and structural elements. These parts must withstand extreme temperatures, pressure changes, and constant vibrations. With custom CNC milling, manufacturers can create highly durable components that comply with strict regulations and performance requirements. The technology ensures that each piece is crafted with exceptional accuracy, minimizing the risk of failure in critical applications.

Additionally, the ability to work with specialized materials such as titanium, aluminum alloys, and heat-resistant composites makes CNC milling a preferred choice in aerospace production. Custom CNC milling enables faster prototyping, allowing engineers to test and refine designs more efficiently. This reduces development time for aircraft and defense equipment while ensuring optimal functionality. As the industry continues to push the boundaries of innovation, CNC milling remains a vital tool for creating reliable, high-performance components that meet the rigorous demands of aerospace operations.

Automotive Manufacturing

Automotive manufacturers heavily depend on custom CNC milling to produce essential components used in engines, transmissions, suspension systems, and interior parts. The technology provides maximum precision, which is necessary for ensuring vehicle safety, fuel efficiency, and overall performance. Through CNC milling, automakers can produce prototypes and final parts with consistent quality, even when dealing with complex designs or advanced materials. This capability allows automotive companies to innovate more quickly while maintaining strict production standards.

In addition, custom CNC milling supports the growing trend of personalization within the automotive industry. Consumers increasingly demand customized features such as tailored interior trims, performance enhancements, and unique exterior elements. CNC milling allows manufacturers to produce one-off or limited-edition components without disrupting the overall assembly process. The flexibility of CNC machines also helps automakers adapt to evolving technologies, such as electric vehicles, which require new types of parts and materials. Ultimately, CNC milling drives efficiency and innovation across the automotive sector.

Medical and Healthcare Sector

The medical and healthcare industry relies heavily on precision manufacturing for devices, implants, surgical instruments, and diagnostic equipment. Custom CNC milling ensures that each component meets the highest standards of accuracy, which is crucial for patient safety and device effectiveness. The ability to produce intricate shapes and micro-scale components makes CNC milling indispensable for creating items such as orthopedic implants, prosthetic joints, dental crowns, and surgical tools. These products often require biocompatible materials like stainless steel, titanium, and specialized polymers—all of which are easily managed with advanced CNC machines.

Moreover, custom CNC milling significantly benefits the medical field by enabling rapid prototyping and faster product development cycles. This is particularly valuable in an industry where innovation directly impacts patient health. Engineers and medical device designers can test new ideas, refine concepts, and bring products to market more quickly. CNC milling also supports the creation of highly customized medical solutions tailored to individual patient needs, such as custom implants and dental prosthetics. With rising demand for precision and personalization, CNC milling continues to play a transformative role in healthcare manufacturing.

Electronics and Technology Industry

The electronics sector depends on custom CNC milling for manufacturing complex components used in consumer electronics, industrial machinery, and communication devices. CNC milling enables the production of high-density enclosures, heat sinks, circuit housings, connectors, and frames with extreme accuracy. As electronic devices become increasingly compact and powerful, the need for precise, miniaturized parts rises. CNC milling allows manufacturers to work with aluminum, copper, plastics, and advanced composites to create components that meet strict dimensional and structural requirements.

Additionally, custom CNC milling plays a crucial role in producing prototypes for new tech products. Rapid prototyping allows engineers to evaluate design functionality, test thermal performance, and refine product aesthetics before mass production. In industries where innovation moves quickly, reducing development time is essential. CNC milling also supports emerging technologies such as robotics, IoT devices, and wearable tech. The ability to create small-batch, high-precision parts helps tech companies innovate continuously while maintaining product reliability and durability.

Industrial Equipment and Machinery Manufacturing

Industrial equipment manufacturers depend on custom CNC milling to produce large, durable components used in heavy machinery, production lines, and automation systems. These industries require parts that can withstand continuous use and harsh working environments. CNC milling is ideal for producing gears, brackets, housings, engine blocks, and mechanical assemblies with exceptional accuracy. This precision ensures that machinery operates smoothly and efficiently, reducing downtime and maintenance costs for industrial operations.

Furthermore, custom CNC milling supports the production of specialized machine parts tailored to specific industrial processes. As factories adopt automation and integrate advanced systems, the need for custom-built components grows. CNC milling enables manufacturers to modify or create entirely new parts that optimize machinery performance and production efficiency. Whether it’s a unique fixture for a production line or a replacement component for aging equipment, CNC milling ensures consistent quality and rapid delivery. This makes it a cornerstone of modern industrial manufacturing.

Conclusion

Custom CNC milling has proven indispensable across a wide range of industries, offering unmatched precision, reliability, and adaptability. From aerospace engineering to medical device production, the ability to craft highly accurate and complex components has transformed manufacturing processes worldwide. Industries benefit not only from improved product quality but also from reduced development times and enhanced customization capabilities. As technology continues to evolve, custom CNC milling will remain a critical driver of innovation and efficiency.

By enabling manufacturers to push the boundaries of design and functionality, CNC milling supports the growth of businesses and the improvement of products across all sectors. Whether improving aircraft safety, advancing medical treatments, or powering next-generation electronics, custom CNC milling continues to shape the future of modern manufacturing.